Proper storage of cleaning equipment is a critical aspect in the food industry, and for good reason. Global food safety standards such as BRC require that cleaning tools are stored in a hygienic way.

- BRCv8: 4.11.6 – 'Cleaning equipment shall be cleaned and stored in a hygienic manner.'

Failing to meet these requirements can lead to non-conformances. From my experience, maintaining the hygiene of your cleaning tools makes sense and offers many benefits:

- Improving cleaning standards,

- Reducing product rejections,

- Increasing cleaning efficiency,

- And ultimately protecting your brand image.

I often visit various customers who produce everything from artisan bread to airplane parts, and they frequently ask me which tool storage solutions I would recommend for their site. My answer is usually a hygienically designed wall bracket or a robust shadow board — both are highly effective and help create a clean, organized, and efficient working environment.

So what do I recommend? Here are some of the tool storage solutions available from Vikan, designed to increase cleaning efficiency, reduce damage to tools, and prevent cross-contamination:

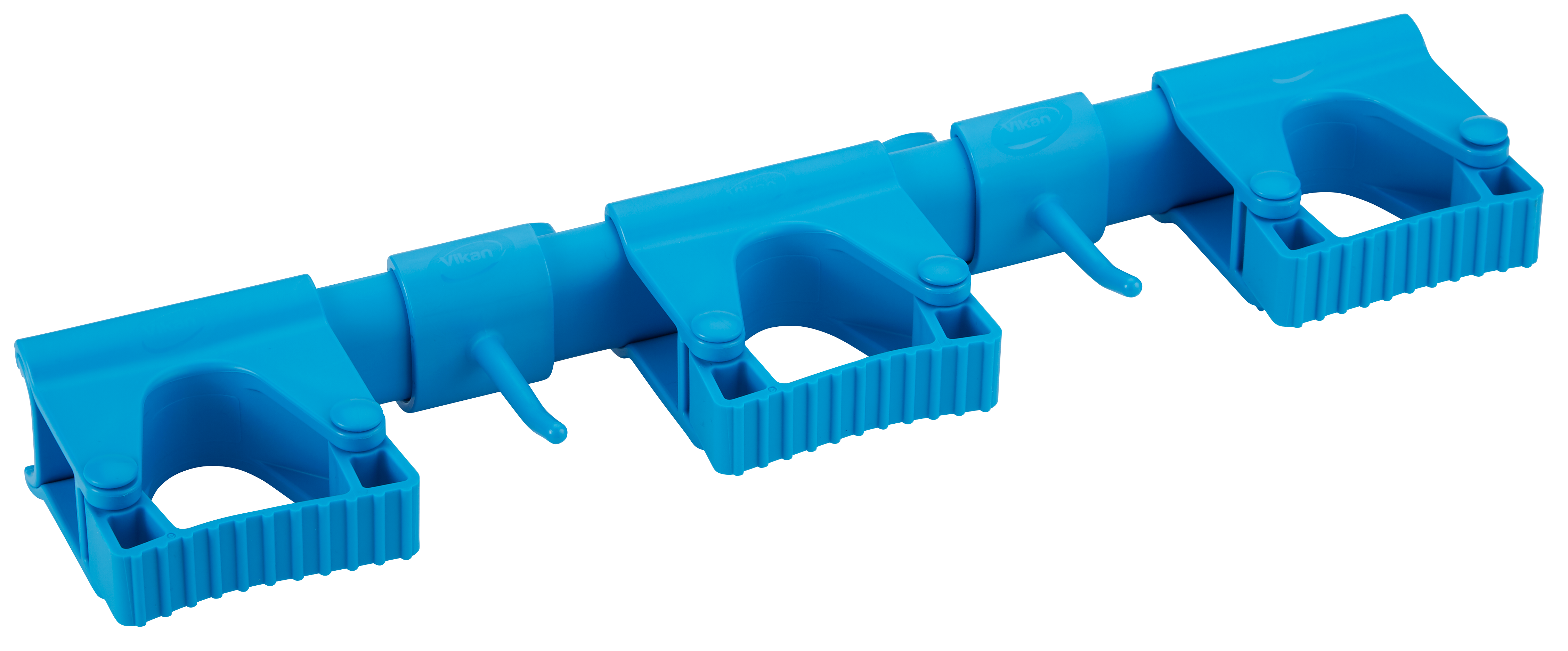

Fully Color Coded Wall Brackets

- Perfect for production areas with limited space

- Color-coded and can match your Vikan tools to optimize segregation and minimize cross-contamination

- Easy to access and audit

- Small footprint but large capacity

See Color Coded Wall Brackets

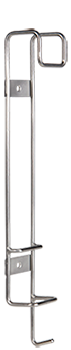

Stainless Steel Wall Brackets

- Robust, durable, and hygienically designed

- Perfect for production areas with limited space

- Small footprint but large capacity

- Tools are easily accessible

- Not color coded

See Stainless Steel Wall Brackets

Shadow Boards

- Available as fixed or mobile versions

- Color-coded, with options for colored shadows or backgrounds

- Tools are easily accessible

- Robust and easy to clean

- Helps identify where each tool belongs

- Supports 5S principles by offering instant management and auditing visibility

Bucket Bracket

- Perfect for storing Vikan’s 6L (5688x) or 12L bucket (5686x) when filled

- Also suitable for 6L 5688x, 12L 5686x, and 20L 5692x buckets, hung upside down after cleaning

- A small hook on the bracket allows for lid or brush storage, ensuring optimal hygiene

- Robust, durable, and hygienically designed

- Constructed from stainless steel

- Easy to install for an accessible cleaning station or storage solution

- Not color-coded

See Bucket Bracket

My top tips below will help you make an informed decision on the tool storage most suitable for your site:

- Understand the ‘flow’ of your operation in detail – When designing your cleaning procedures, ensure your storage accommodates only the tools required for cleaning each specific area of your site. Learn more about how the 5S principles of Sort, Straighten, Shine, Standardize, and Sustain can improve your operational efficiency.

- Tight on Space? A tool bracket or a mobile shadow board might suit your requirements more than a wall-mounted shadow board.

- Look for Hygienic Design – Our stainless steel and shadow board options are designed with hygiene in mind, making them easy to clean and maintain.

- Double Storage - Mobile shadow boards can be double-sided so you can hold non-food contact hygiene tools on one side and food contact hygiene tools on the other – effective and efficient.

- Only One Colour – For best practice, only have one colour of hygiene tool on each tool bracket holder or shadow board – this prevents any potential cross-contamination issues.

- Glass breakages and Allergen Spills – Shadow boards are great for storing emergency spill kits. Position the shadow board prominently near a potential hazard for easy access when needed.

- Stainless Steel Hooks are recommended for tool storage on shadow boards – they are hard wearing and prevent hygiene tools from slipping off.

- Working in a Damp Environment? All our storage solutions will stand up to the rigors of being foamed and washed on a daily basis compared to cheaper alternatives.

- Last but not least Equipment Storage – To prevent hygiene issues, it's always a good idea to follow these guidelines:

- Equipment should be stored head down to prevent contamination running down the handles and cross-contaminating from there to the hands.

- Similarly, the head of equipment should be stored with their heads distant from other equipment handles.

- Equipment should be arranged on the rack/board in a way that prevents equipment above dripping contamination onto hygiene-critical surfaces of the equipment below.

- Our shadow boards can be quite tall, so make sure that smaller equipment is placed within easy reach.

For more information on the most effective hygiene tool storage for you, please contact myself, Ally Scott at .

Recent blog posts

Buckets, buckets everywhere

Don’t rush. Take a breath and start paying careful attention to the buckets used in the food and beverage sector.

Efficient and Effective Wall Cleaning in Your Factory

When it comes to cleaning walls in your factory, forget hiring a cherry picker and scrubbing with hand cloths — Vikan has a solution that removes dirt easily and effectively in a short amount of time.

Which Squeegee Do I Choose?

Finding the right Vikan squeegee for the right job helps raise hygiene standards and boosts your employees' job satisfaction.

Premium Charcoal Grill,Authentic BBQ Charcoal,Outdoor Charcoal Grill

GFTOP , https://www.ovenchief.com